The reason why machine guarding system is so important is that it greatly improves workers' safety. With this system, workers can free from worries about crushing injuries, amputation, or sudden death risks while performing specific tasks. As a result, this move enables workers to maximize their production efficiency and accelerate the company growth.

Machine guarding system impact resistance testing

In order to make all our modular panels are stable and able to withstand harsh conditions, all our panel series are subjected to rigorous quality testing to ensure that these panels are durable and stable under extreme impacts.

Machine guarding system impact resistance is tested in strict accordance with BS EN ISO 14120-2015 Standard.

Machine guarding system typically performs two functions, to prevent persons from accessing to the hazard zone and to contain part of the machine within the guarded zone. This article gives guidance for both cases.

The guidance given in this article is relevant only when an impact hazard exists and only applicable to machine guarding systems.

The test method gives guidance for soft and hard pendulums which represent impacts at lower velocity rather than high velocity impact by ejected part of machinery or materials.

The test equipment consists of a soft or hard pendulum and mesh panels to be tested.

The pendulum test method is used to test the resistance of machine guarding systems against impacts from outside the guarded hazard zone and from inside the hazard zone.

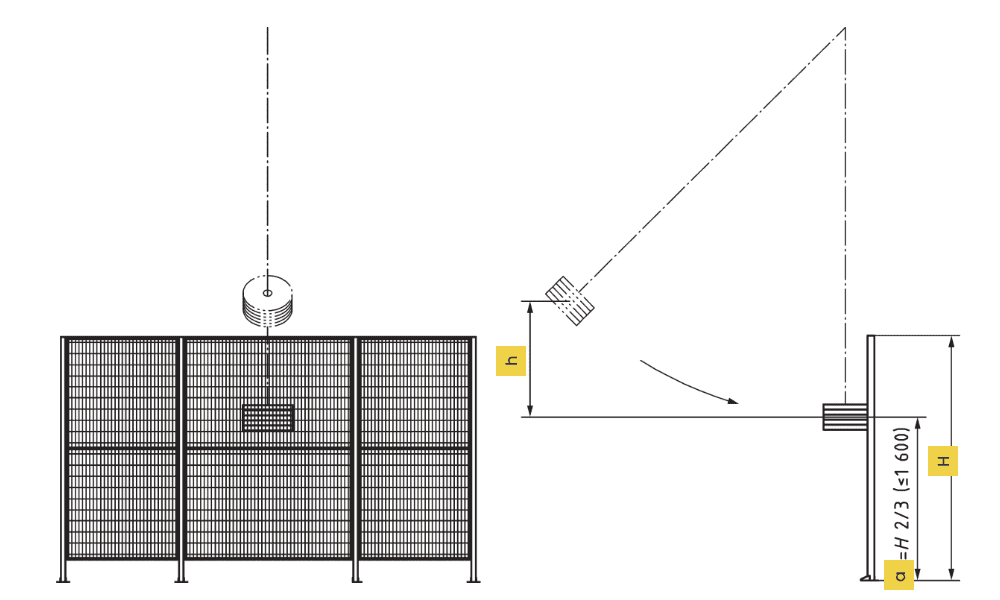

The test method is based on the impact of a "body", which might be a human body (soft body) or a part of a machine (hard body) falling under the effect of gravity to simulate contact by the human body with the machine guarding system or part of the machine with the machine guarding system.

This test is developed for vertical machine guarding system. However, it might be applicable to horizontally mounted machine guarding system if the application of the test load is compatible with the loading foreseeable in use.

The mesh panel to be tested shall be mounted in the test rig in accordance with its machine guarding application. If no specific value exists, the mesh panel to be tested shall be mounted in the test rig between two posts. The mesh panel shall be at least 1000 mm wide between the posts. The posts shall be fixed to a solid base. The pendulum is adjusted so that the impact hits the mesh panel at 2/3 of the total panel height above the floor or corresponding plane, but not higher than 1600 mm.

Test impact energies depend on the machine itself and shall be calculated by using the basic formulae for energy:

or

NOTE: The energy calculated represents the energy just before impact.

Sample of hard bodies showing impact area

After the test, the damages found on the machine guarding system or material shall be assessed.

The damages may consist of the following:

The test is passed if

Test report

The test report should give the following minimum information:

It should be noted that the results are valid only for the test object. The conclusions for use of the machine guarding in a specific application are made by the machine designer.

All our mesh panel series undergo strict pendulum tests. During the test, a pendulum weighing 160 kg hits the mesh panel at a speed of 20 miles/hour. The test results prove that our mesh panels can withstand the impact of up to 2500 J. You can purchase our machine guarding systems without further worries.