Machine Guarding System for Industrial Safety with Advanced Standards

Our machine guarding system is developed to meet the needs of modern industrial safety. The following sections outline its applications, strengths, manufacturing process, and technical standards.

Fencing Technical Standards

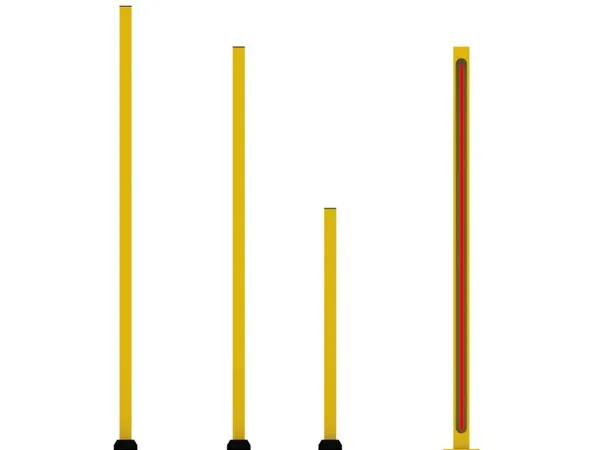

Upright Posts

- Material: 60 × 60 mm cold-rolled seamless steel tube

- Thickness: 1.5 mm

- Requirement: Burr-free cutting, smooth edges

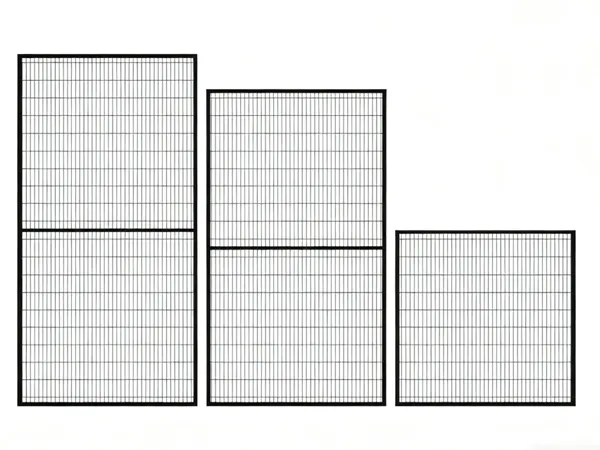

Fence Frames

- Material: 20 × 20 mm square tube

- Welded using automated equipment

- Weld quality: uniform, firm, with no sharp edges or protrusions

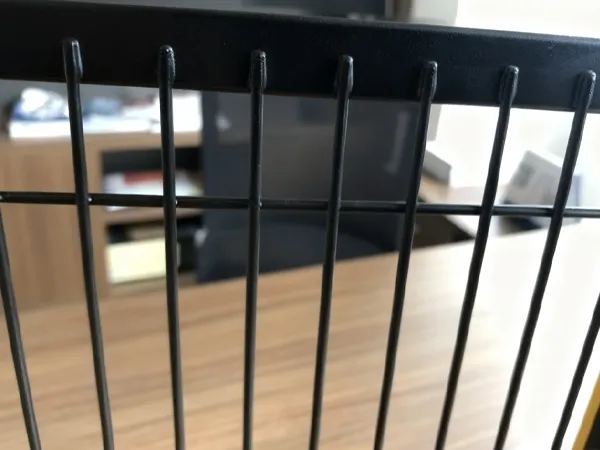

Mesh Panels

- Material: 3 mm steel wire

- Opening size: 100 × 20 mm

- Meets industrial safety protection requirements

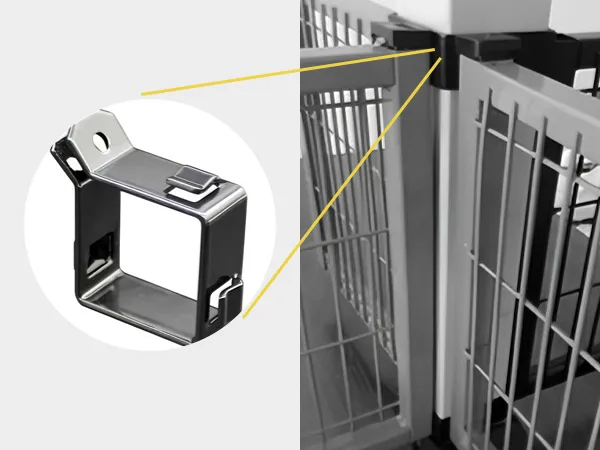

Connection System

- Mesh panels are secured to the upright posts using snap rings connectors.

- Supports multi-direction connection on a single post

- Easy to install, adjust, and maintain

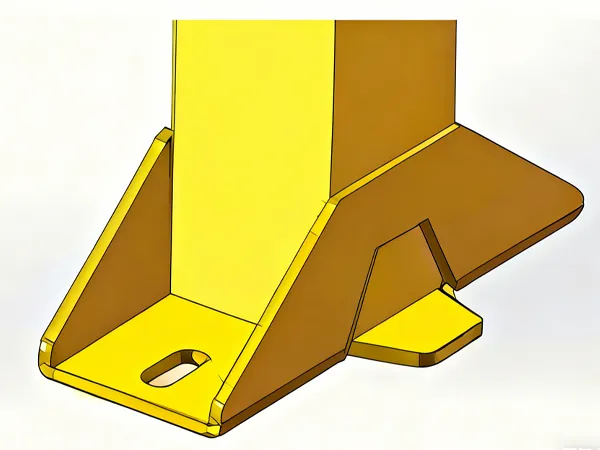

Base Plate

- Size: 70 × 180 mm

- Installed with two M10 × 100 metal expansion bolts

- Side-ear structure improves stability of the upright post

Production Process

- CNC Precision Cutting: Square tubes are cut using CNC automatic fixed-length cutting saws, ensuring minimal dimensional error and burr-free edges.

- Automatic Welding of Frames & Posts: Automatic welding machines ensure uniform weld seams, high bonding strength, and increased production efficiency.

- Mesh-to-Frame Welding: Mesh panels are welded to frames with specialized mesh-welding equipment. The process supports multiple specifications and produces clean joints with no weld beads or slag.

- Surface Pretreatment (Shot Blasting): Shot blasting removes oil, rust, and surface stress, significantly improving powder-coating adhesion.

- Fully Automatic Powder Coating Line: Advanced powder-coating technology ensures a uniform finish with excellent leveling and surface performance.

- Protective Packaging: Mesh panels are separated with bubble film to prevent friction, scratching, and collision damage during transportation.

Core Advantages

- Strong corrosion prevention, integral welding molding, corrosion resistance, long service life.

- Simple installation, modular design, convenient installation.

- Beautiful and applicable, the perfect combination of ingenious structural design and strict production control.

- Exquisite workmanship, resistance welding, plastic spraying and other technologies.

- Tailor-made, plan drawing design according to layout requirements.

Application

Our fencing systems are widely used in industrial production areas, including:

- Workshop isolation fence

- Warehousing and logistics fence

- Protective fence for large equipment

- Protective fence for arc-welding rooms

- Automation safety fence for automobile manufacturing

- Automatic production line fence

- Automatic welding line fence

These systems help achieve personnel protection, equipment isolation, hazard control, and production-line safety zoning.