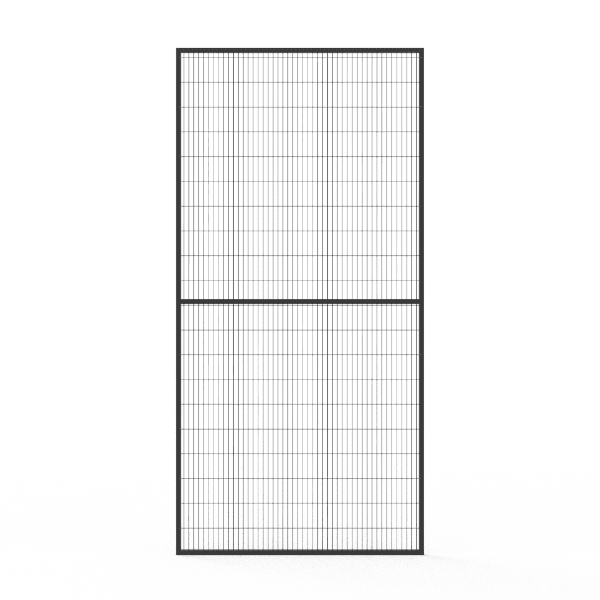

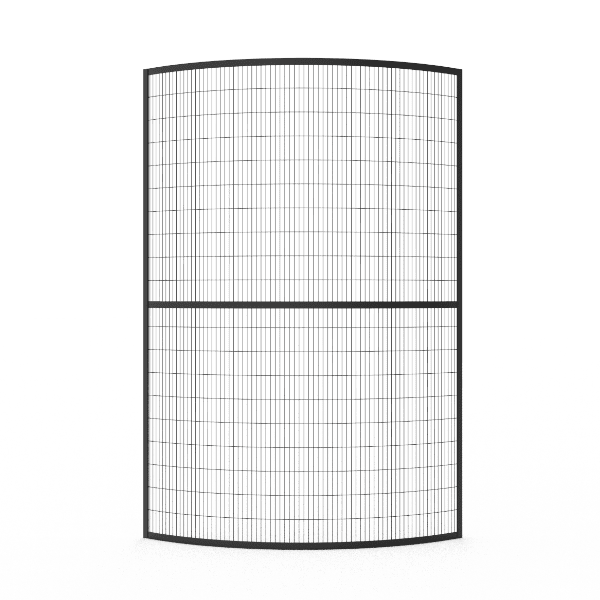

Our mesh panels are divided into standard mesh panels and corner panels. Every mesh panel has its own advantages, how to choose a proper panel that is perfect for your working environment? You may find your answer by reading the following comparison table.

| Standard Mesh Panel | Corner Panel | |

|---|---|---|

| Img |

|

|

| Features |

|

|

| Applications | It can be used in all flat surfaces of machine guarding systems and warehouse partitions as well as corners without space limitation. | It is suitable for machine guarding system corners with strict space restrictions and high safety requirements. |

| Manufacturing Techniques | Mesh panel is welded to the frame. | Mesh panel is welded to the frame and then bent into a corner panel with 90° fillet angle. |

| Costs | It costs less when compared with the corner panel of the same size. | As an added production process is required, therefore, it costs higher when compared with the standard mesh panel of the same size. |

| Mesh Panel Type | Weld-mesh panel or crimp-mesh panel | Weld-mesh panel or crimp-mesh panel |

| Panel Height | 2000/2200/2500 mm | 2000/2200/2500 mm |

| Wire Diameter | 3.0/4.0/5.0 mm | 3.0/4.0/5.0 mm |

| Frame Type | Pipe frame or angle frame | Pipe frame or angle frame |

| Finish | Powder coating | Powder coating |

| Color |

Standard is RAL 9005 black.  Other RAL colors are available. |

Standard is RAL 9005 black.  Other RAL colors are available. |

By reading the comparison table above mentioned, we can conclude that

If you have any doubt, please contact us, we are ready to help you at any time.