If you do not know whether you need a machine guarding system, you may try to answer the following questions.

If you answered yes to any of these, then you need a Metan machine guarding system.

Improper machine guarding is one of the most frequent causes of OSHA citations. You are obliged to provide a safe working environment. If failing to do so, you may get hefty penalties, production losses, increased insurance premiums, or worst of all, serious personal injury.

According to EU 2006/42/EC – New Machinery Directive and OSHA Occupational Safety and Health Administration regulations, two main principles on safety of machinery are set as shown below:

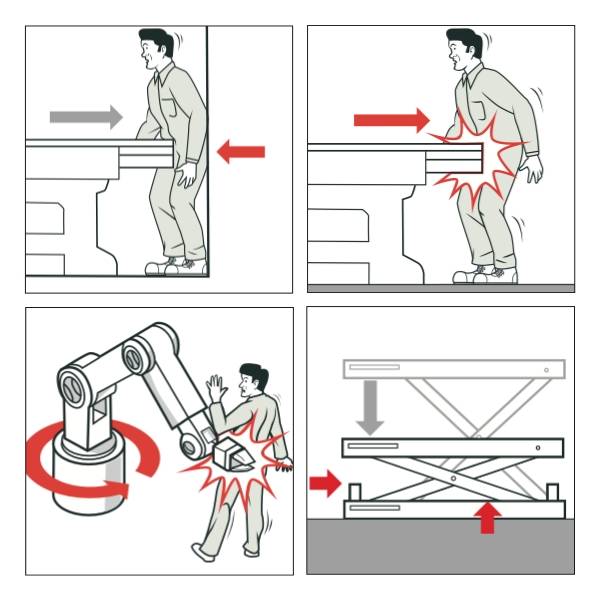

The reason why machine guarding system is so important in workplaces is that it significantly improve the safety of workers in production. With them, operators do not have to worry about crushing injures, amputation or death while performing specific tasks. It enables workers to maximize their working efficiency and greatly promote the development of the company. Therefore, machine guarding systems must be installed on workplaces in accordance with relevant standards and regulations to avoid safety accidents.

The first step to avoid potential safety citations and illegal actions is to know what kind of machine guarding system your workplaces needs. Metan's modular design creates machine guarding systems that comply with prevailing OSHA, ISO, EN, ANSI, RIA and CSA standards.

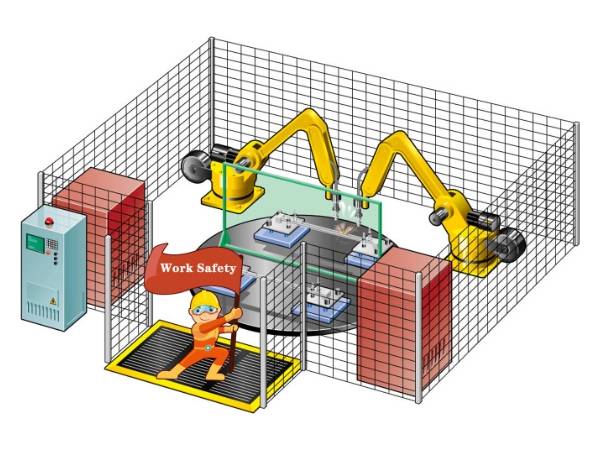

Our machine guarding system mesh panels adopt weld-mesh panels or crimp-mesh panels, offering users a clear and unobstructed view. In addition, it allows users to clearly observe the operation of mechanical machinery inside the machine guarding system. Moreover, it allows light, air and spray water of the fire extinguishing system passing through easily. Mesh panels work with posts to maintain its structural stability in the best way and give users greatest sense of security, thereby making them work more efficiently.

In addition, modular installation is adopted to allow machine guarding system occupying minimum floor area and achieving maximum security according to your specific working environment.

In consideration of machine maintenance, all our machine guarding systems are provided with a variety of easy-access doors to facilitate serviceman in and out for maintenance.

To sum up, Metan machine guarding system is your great choice for protecting your workers' safety as it helps to lower and eliminate potential hazards in production, reduce downtime, improve your working efficiency and bring higher profit for your company.